Features

| Red light spot fast positioning, CCD display. |

| High working speed: 6 times faster then traditional TOG or MIG welding. |

| Slight distortion and less heating affect. |

| Capable of partial heating process. |

| Able to deal with complex, profiled, or tiny letters. |

| Low noise and no pollution. |

| Ultra fine positioning rod makes corner welding easier without changing position. |

| Laser cavity can move in all directions manually in order to weld letters of different size and in different shape. |

| Parameter setting in very easy; up to 10 sets of parameters can be memorized for different application. |

Technical Specification

| Model | WY200 / FT | WY300 / FT | WY400 / FT |

| Rated Power | 200W | 300W | 400W |

| Laser Source | Pulses Nd:YAG | ||

| Output Optical Path | Single Path (standard) | Double Path (standard+fiber) | Single Path (standard) |

| Laser Wavelength | 1064nm | ||

| Single Pulse Energy | 80J | 100J | 120J |

| Working Table Scale | 750mm x 1000mm | ||

| XYZ Stroke | X=700mm, Y=200mm, Z=200mm (manual) | ||

| Power Supply | 220V±10%/50Hz | 380V±10%/50Hz | |

| Power Consumption | 6KW | 9KW | 12KW |

| Beam Diameter | 0.1~3.0mm | ||

| Pules Width | <15ms | ||

| Pulse Frequency | 1~50Hz | ||

| Focal Length | 150mm / 200mm | ||

| Cooling System | Water Cooling | ||

| Observation System | CCD Camera | ||

| Packaging Dimensions | 1160x610x1150mm | 1540x950x1150mm | 1260x710x1150mm |

| Gross Weight | 319kg | 329kg | 342kg |

| Specifications are liable to change without prior notice. | |||

Immediate Contact No.

072290 93988 / 092276 78044

072290 93988 / 092276 78044

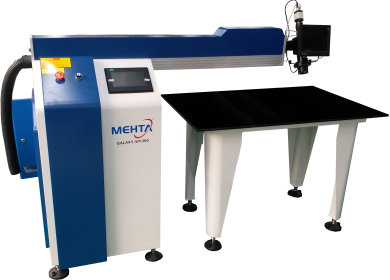

YAG Laser Welding Machines