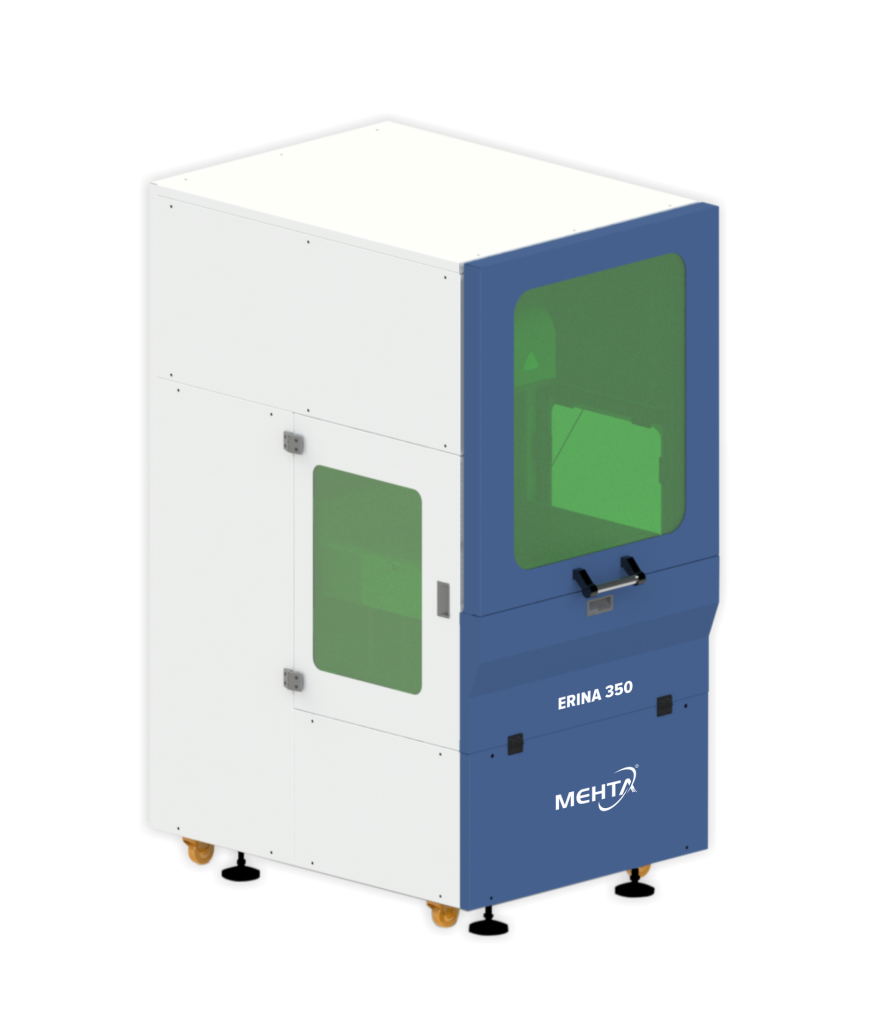

High Speed Laser cutting and Engraving Machine (3D scan head system)

ERINA 100

Features

| Principle of dynamic focusing system is to daynamically control the laser beam divergence angle by a group of optical beam expander lens, so as to make the focusing laser spot on the different position of marking area or curved surface coordinate uniform. Usually in the design, optical lens group consists of 3 pieces of focusing lens. Back focus lens is consist of two pcs of aspherical lenses, which can eliminate spherical aberration, and can obtain better beam quality; the front negative focusing lens is controlled by software, driven by the high speed rod motor, do the reciprocating motion, compensating the corresponding laser spots on the marking platform point by point. |

| With high speed digital galvo, combined with dynamic shaft drive, can realize the large area work size marking and 3d surface marking. |

| Optimization of optical design and optical lens combination, reduces optical loss and component costs, as well as improves laser use efficiency. |

Technical Specification

| Model | ERINA 100 | ERINA 150 | ERINA 250 | ERINA 350 |

| Laser Power | 100W | 150W | 250W | 350W |

| Laser wavelength | Co2 RF Laser Metal Tube 10.6 um | |||

| Working area | 400 x 400 mm to 600 x 600 mm | 400 x 400 mm to 1200 x 1200 mm | ||

| Scan Head | 3D Dynamic Galvo System | |||

| Cooling Method | Water Cooled | |||

| Max. Speed | Max. 8000 mm/s | |||

| Min. Latter Size | 1 mm | |||

| Repetition Accuracy | 0.01mm | |||

| Graphical Format | PLT, DXF, BMP, JPG, TIF | |||

| Power Supply | PLT, DXF, BMP, JPG, TIF | |||

| Power Supply | 220V / 415V 50Hz / 60Hz | |||

| Operating System | Win 7 / 10 (32bit / 64bit) | |||

| Working Environment | 15°C – 30°C, Humidity 30%-80% | |||

| Consumption | ≤3KW | ≤5KW | ≤7KW | ≤9KW |

| *Specification are liable to change without prior notice. | ||||

Applications

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Immediate Contact No.

092279 85717, 092276 78044

092279 85717, 092276 78044

High Speed Laser cutting and Engraving Machine (3D scan head system)