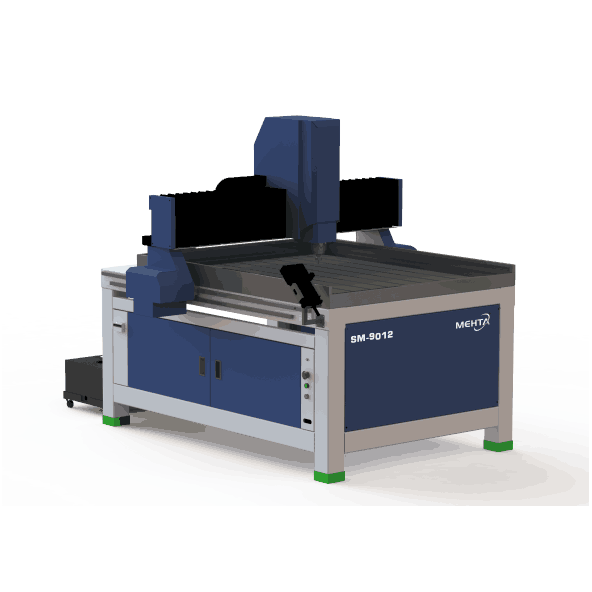

Features

| Profiled steel welded lathe bed, stabilizing treated under artificial prescription ensures minimum distortion, excellent rigidity and vigorous strength. |

| Precise traveling of Y axis driven by double motors ensures stable performance of machine. |

| High precision rack transmission ensures high accuracy, fast speed and strong power. |

| Imported square linear guide rail ensures high accuracy, maximum work load and service time. |

| Best mechanical and electrical design with well selected branded parts with minimum breakdown rate. |

| Overall dust proof and water proof design protects all moving parts of the machine. |

| Ongoing filtration system provided which filters the cutting oil from stone dust and re-circulate cutting oil. |

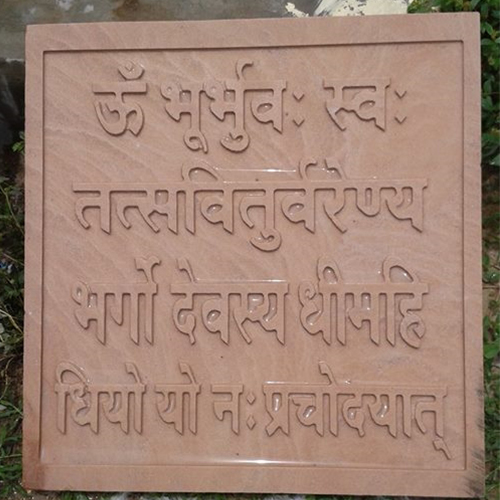

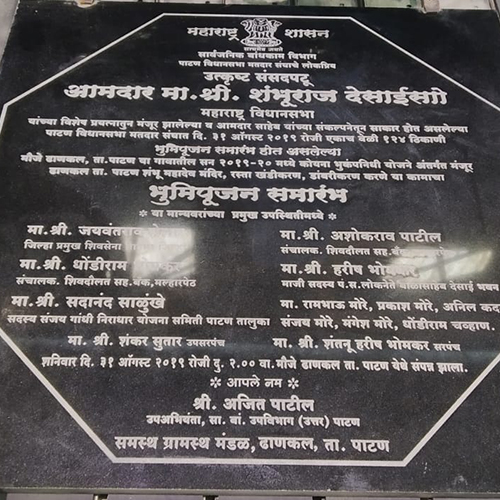

Application

|

|

|

Technical Specification

| Model | SM 9012 | SM 1325 |

| Machining Area | 914 X 1219 mm | 1300 X 2500 mm |

| Spindle | 2.2kw (Water Cooled Spindle) | 5.5kw (Water Cooled Spindle) |

| Spindle RPM | 24000 | 24000 |

| Z Max. Traveling | 150 mm | 300 mm |

| Distance Between Bed and Gentry | 150 mm | 300 mm |

| Cutting Tool Diameter | Ø3 to Ø10 | Ø3 to Ø16 |

| Repeated Location | 0.025 mm | 0.025 mm |

| Max Running Speed | 15m/min | 15m/min |

| Motor | Stepper | Stepper |

| Working Table | Aluminum T-Slot With S S Tray | Aluminum T-Slot With S S Tray |

| Controller | New Advance DSP Hand Controller | New Advance DSP Hand Controller |

| Spindle Cooling Systems | Water Chiller | Water Chiller |

| Power Supply | AC 220V/ 50Hz | AC 420V/ 50Hz |

| Weight | ||

| *Specification are liable to change without prior notice. | ||

Immediate Contact No.

09227985731, 092276 78044

09227985731, 092276 78044

CNC Routers for Stones