Home » Digital Printer » Sign Industry » Solvent / Flex Printers » PRINCE 3202SK / 3204SK

The PRINCE 3202SK/3204SK pair combines flexibility and speed: either two or four Seiko 1024 heads in staggered layout, automatic media feeding, and full-range heating/drying (pre-, mid-, post-) plus IR dryers.

Model : PRINCE 3202SK / 3204SK

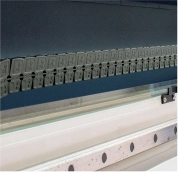

Print Heads : 2 x / 4 x Seiko 1024HG Print Head

Technology : Drop on Demand Peizo Inkjet Technology

High Torque yet Low Vibration; Stable, and Accurate Printing.

CNC Aluminium Beam support with Dual Linear Guides for High Speed Printing.

High density, Sturdy Print head with grayscale technology.

Powerful IR Heater with Enabling High Speed Printing Capability.

Super Precision with Low Friction Noise

Anti Collision System to Protect Print Head during High Speed Printing.

Provides easy-to-use tools to achieve high-quality, consistent color-managed output for your printing.

Platform Suction Adjustable System.

Multi-Heating & Drying System.

High Strength Steel Body Frame and High-Precision Liner Rail.

Electronic Nozzles Flash Control.

Automatic Negative Pressure Adjustment With Individual Cleaning System.

Maximum Four Print Heads In Staggered Way.

| Model | PRINCE 3202SK | PRINCE 3204SK | ||||||||||||||||||||||||

| Print Head | 2 x Seiko 1024HG Print Head | 4 x Seiko 1024GH Print Head | ||||||||||||||||||||||||

| Speed |

|

|

||||||||||||||||||||||||

| Technology | Drop on Demand Peizo Inkjet Technology | |||||||||||||||||||||||||

| Ink | C.M.Y.K Solvent / Eco Solvent | |||||||||||||||||||||||||

| Ink Supply System | Auto Consistent Ink Supply With Negative Air Pressure System | |||||||||||||||||||||||||

| Feeding System | Automatic Media Feeding and Taking up with Infrared Sensor | |||||||||||||||||||||||||

| Drying System | Pre, Mid, Post heater + IR drying system | |||||||||||||||||||||||||

| Printing Width | Max. 3200mm | |||||||||||||||||||||||||

| Media Type | Paper, PVC, Banner, Frontlit, Backlit, Vinyl, Film… | |||||||||||||||||||||||||

| RIP Software | Flexi Print MCC Edition | |||||||||||||||||||||||||

| Image Format | .PDF, .JPEG., .TIIF | |||||||||||||||||||||||||

| Data Interface | External : USB3.0+; Internal: Fiber Optical Cable | |||||||||||||||||||||||||

| Power | Single Phase 50Hz/AC,220V+10% 10A (printer) + 32A (IR drying system) | |||||||||||||||||||||||||

| Working Environment | Temp.23℃~29℃, Humidity:50%~80% | |||||||||||||||||||||||||

| Installed/Package Size | LxWxH(mm): 5000x1200x1520 / 5100x1300x1625 | |||||||||||||||||||||||||

| N.W./G.W. | 1000kgs / 1050kgs | |||||||||||||||||||||||||

+91-79-26840551 / 52 / 53

Domestic : +91-7575009654

International : 7043505091

mktg@mehtaindia.com

International: export@mehtaindia.com

Plot No.3, Road No.1, Kathwada GIDC, Kathwada, SP Ring Road, Ahmedabad-382430, Gujarat, India.

Mehta Hitech Industries Limited

formerly known as Mehta Cad Cam Systems Pvt. Ltd.

CIN – U72200GJ2000PLC038163

If you have any query or complains, please contact our Customer Care Department.

Sign up to receive updates on new product announcements, special promotions, sales, & more!

"*" indicates required fields

Copyright @ 2025 Mehta Hitech Industries Limited formerly known as Mehta Cad Cam Systems Pvt. Ltd. All Rights Reserved.

"*" indicates required fields