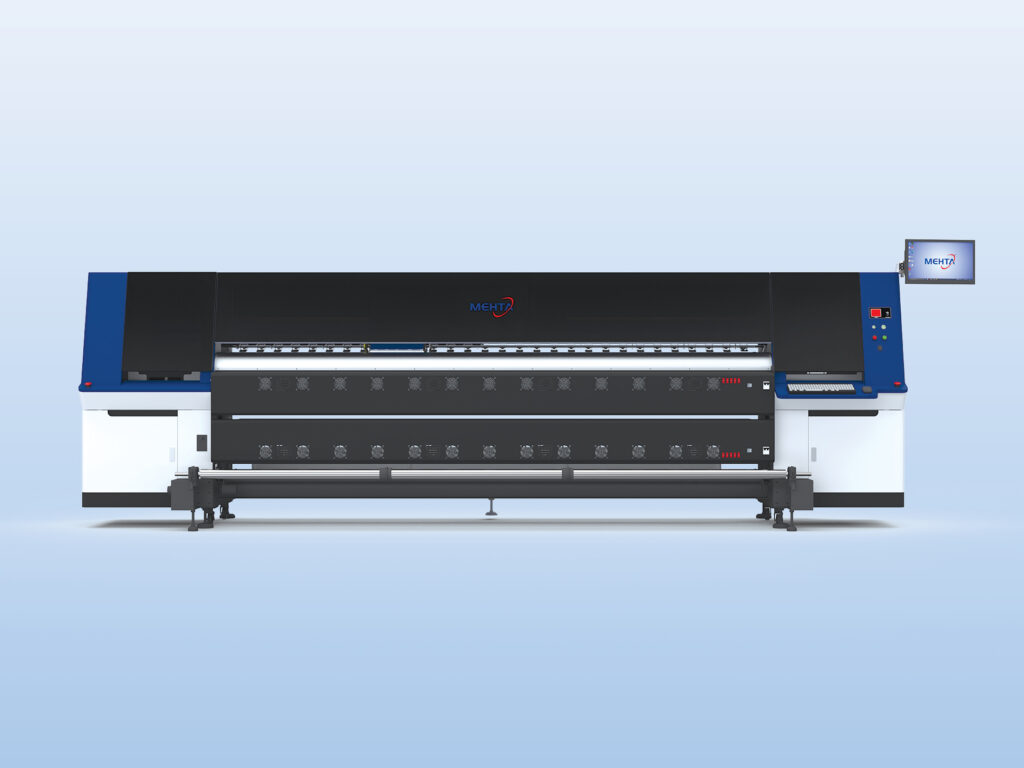

In high-volume solvent printing, the speed of the printer directly affects turnaround time, capacity planning, and daily profitability. Mehta Hitech Industries Limited recently introduced TITAN 3202, which is designed for production environments where output cannot slow down. Built to handle continuous workloads at very high speeds, it combines fast printing with stable ink control and consistent quality, making it a practical choice for businesses that run long hours and tight schedules.

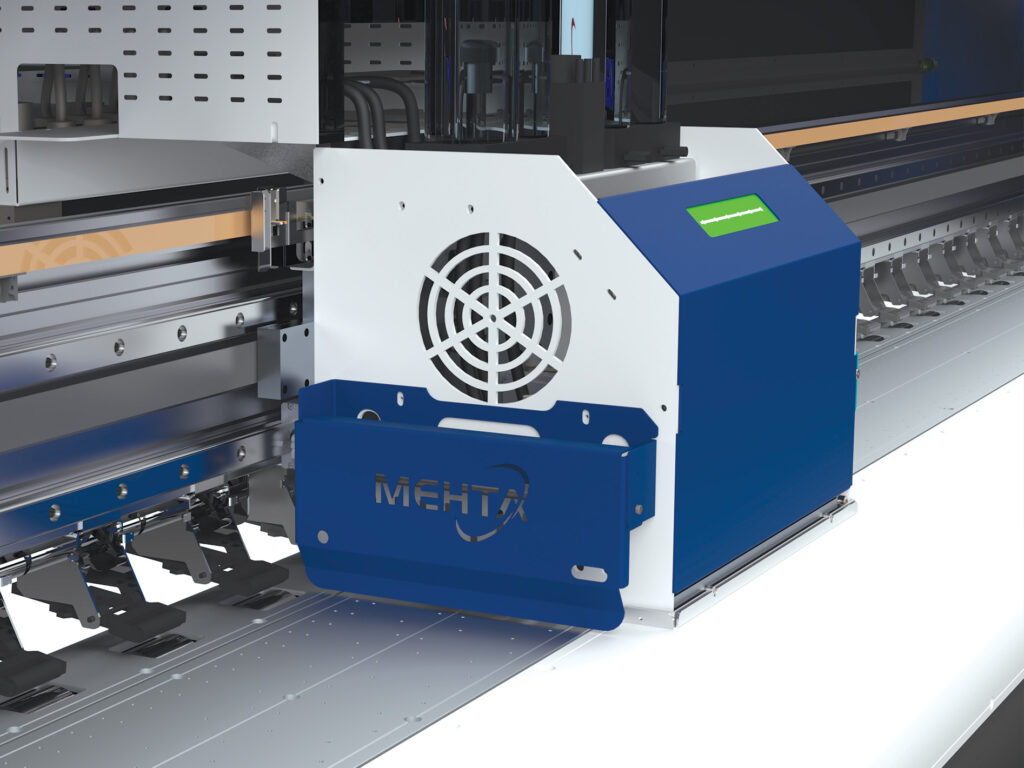

At the core of TITAN is the Seiko RC1536 recirculation printhead. For operators, this directly impacts daily workflow. Recirculation keeps ink moving inside the head, which significantly reduces purging and minimizes clog-related interruptions. When production runs extend across hours or full shifts, this stability helps maintain output without frequent stops for cleaning or recalibration.

TITAN’s configuration supports demanding workloads. With up to four printheads, the system focuses on accurate dot placement rather than pushing speed at the cost of quality. Variable droplet control allows smoother gradients and controlled ink laydown, which becomes noticeable on large-format graphics viewed at close range. Across its 3.2-meter print width, consistency remains uniform, even during continuous operation.

Speed, however, remains a defining factor. TITAN can reach production speeds of up to 4050 square feet per hour, making it suitable for facilities handling bulk signage, banners, and outdoor graphics. This output level helps production teams meet deadlines without relying on multiple machines or extended overtime shifts.

Drying and material handling also influence real-world productivity. TITAN integrates IR heaters with drying fans, supported by an external IR heating system. This combination ensures ink dries evenly, reducing smudging and rework. Prints come off the machine ready for handling, trimming, or finishing, which keeps downstream processes moving smoothly.

Maintenance demands often shape long-term operating costs. TITAN’s sealed ink channels and thermal control system are designed to maintain stable ink flow throughout the day. For operators, this translates into fewer interruptions, longer printhead life, and predictable performance rather than sudden quality drops mid-job.

Connectivity plays a supporting role. Through the Mehta One app, users place consumable orders and raise service requests without disrupting production schedules. It simplifies coordination between production, maintenance, and support teams.

TITAN 3202 is built for environments where reliability, high speed, and consistency is required. For print businesses managing large volumes and tight timelines, these factors often matter more.

For print businesses evaluating high-volume solvent printing solutions, TITAN 3202 offers a practical balance of speed, stability, and operational control. To learn more about the machine or discuss specific production requirements, contact Mehta Hitech Industries Limited.

Call: +91 75750 09654

Email: mktg@mehtaindia.com